Gray Hall at Grand Forks Air Force Base has achieved LEED Silver certification!

LEED (Leadership in Energy and Environmental Design) is the most widely used green building rating system in use throughout the world. As with other third-party certification organizations, LEED provides a framework that project teams can apply to create healthy, efficient, and long-term green buildings.

The project included a complete renovation, transitioning an existing dormitory to apartments for the service personnel at Grand Forks AFB. The building, which had been out of service for several years, is up and running again.

EAPC served as the LEED consultant to the general contractor, ProMark Services Inc. of West Fargo. We were also responsible for reviewing the project process to confirm sustainable design goals were met and completing the documentation for LEED® certification.

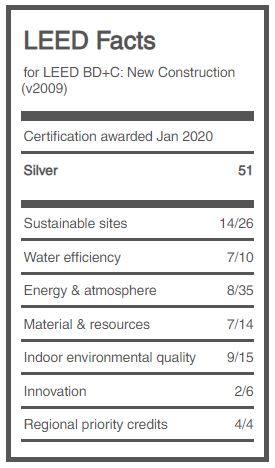

In doing so, EAPC team members reviewed and submitted LEED credits in seven categories: Sustainable Sites, Water Efficiency, Energy and Atmosphere, Materials and Resources, Indoor Environmental Quality, and Innovation in Design. The project also earned bonus points for meeting regional priority credits specific to the 58204 zip code area. Gray Hall earned Silver Certification with 51 credits under LEED®v2009.

Check out the LEED project scorecard to see the goals achieved

Highlights of the project include an actual energy savings of 29.1% when compared to a baseline building and a cost savings of 18%. EAPC reviewed the design and created an energy modeling for evaluation. The energy savings were achieved with the installation of the geothermal system, LED lighting, and improvements to the exterior building shell that included the addition of insulation at the exterior walls and higher performing windows.

Another highlight of this LEED Silver certification was the contractor’s ability to divert 78% of the construction waste from the landfill. The existing building was primarily constructed of concrete masonry units (cmu) at both interior and exterior wall systems, and the removed material was sent to an aggregate company which will use the ground cmu as aggregate for concrete paving. Along with that, most metals were diverted to a recycling company.