As part of a strategic alliance with a leading ethanol engineering and technology organization in the United States, EAPC provided engineering and design services to support the expansion of the ethanol industry from 2001 to present. EAPC has provided services to approximately 90 ethanol greenfield plants and plant expansions in the US and internationally including an isobutanol plant. Multiple plants were in the design phase in various phases of completion by EAPC during this expansion of the ethanol industry. These ethanol plants range in capacity from 30, 40, 50, and 100 million gallons per year. EAPC also supported other facility owners and engineering service providers in ethanol and biodeisel production throughout this period of time.

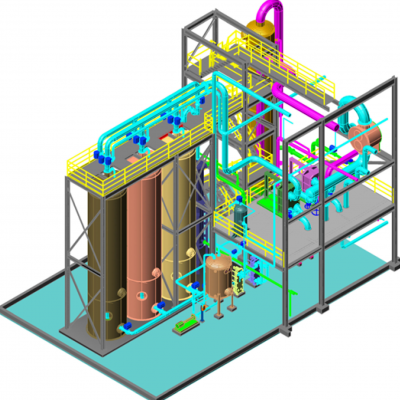

Since 2001, EAPC’s support services were broad in nature encompassing mechanical, piping, electrical, structural engineering, design and architectural including onsite support. EAPC’s team also has provided process engineering support including start up assistance, process troubleshooting and computer modeling using ChemCad and Design II, factory debottlenecking efforts, energy efficiency improvements and detailed engineering design of unique processing equipment.

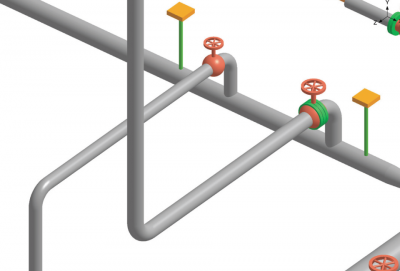

EAPC provided 3D plant modeling and design utilizing Intergraph’s CADWorx software. Plan and elevation drawings were produced as well as single line isometric drawings with bills of materials and enhanced production and efficiency was gained via ISOGEN isometric production. EAPC provided piping analysis services including ASME B31.1 and B31.3 integrating the use of Intergraph’s Caesar pipe stress analysis software. ASME Section VIII pressure vessel and API 650 tank engineering, design and analysis services were also provided for plant pressure vessel and tank equipment requirements utilizing Intergraph’s PV Elite and Tank/Tank Fabricator software. Piping and piping specialty specification development support including conversion of US to European standards was provided.

Civil, Structural and Architectural engineering and design support for buildings, piping piers, tunnels and trusses, including concrete foundation and structural framing and platforms, building code review and construction support services was provided. Electrical lighting, power, cathodic protection and lightning protection services were included.