Eliminating errors, reducing time, and decreasing costs all for the benefit of our clients.

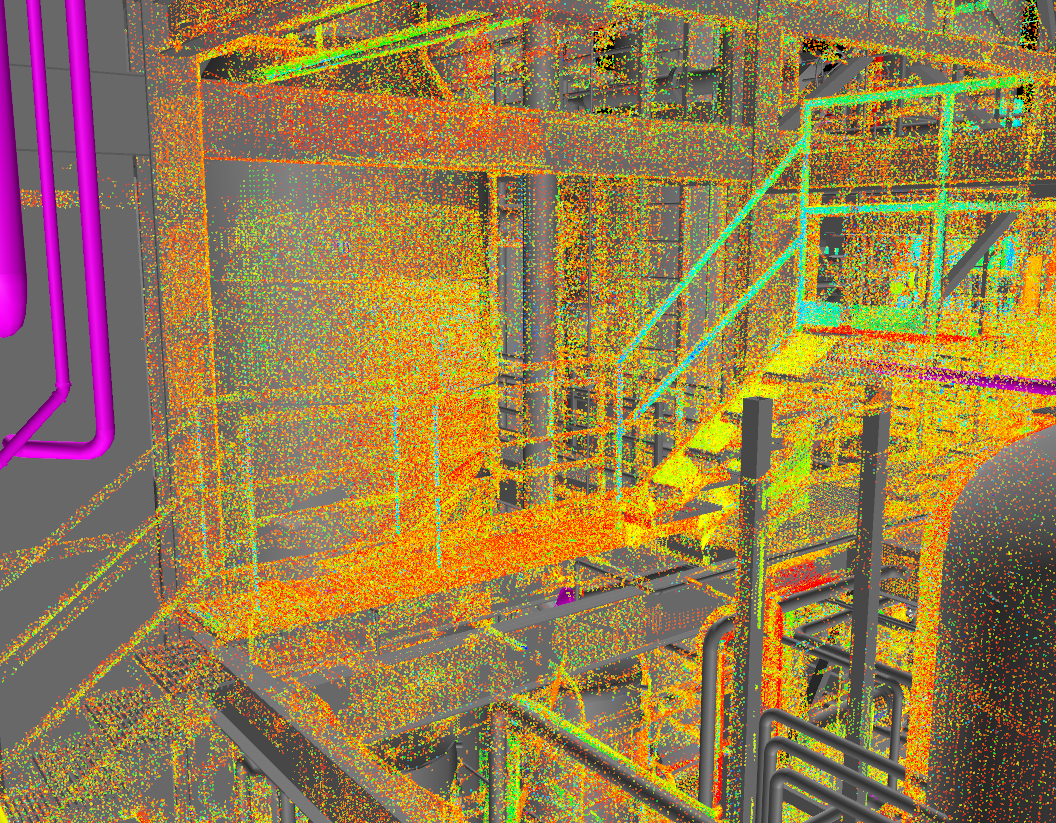

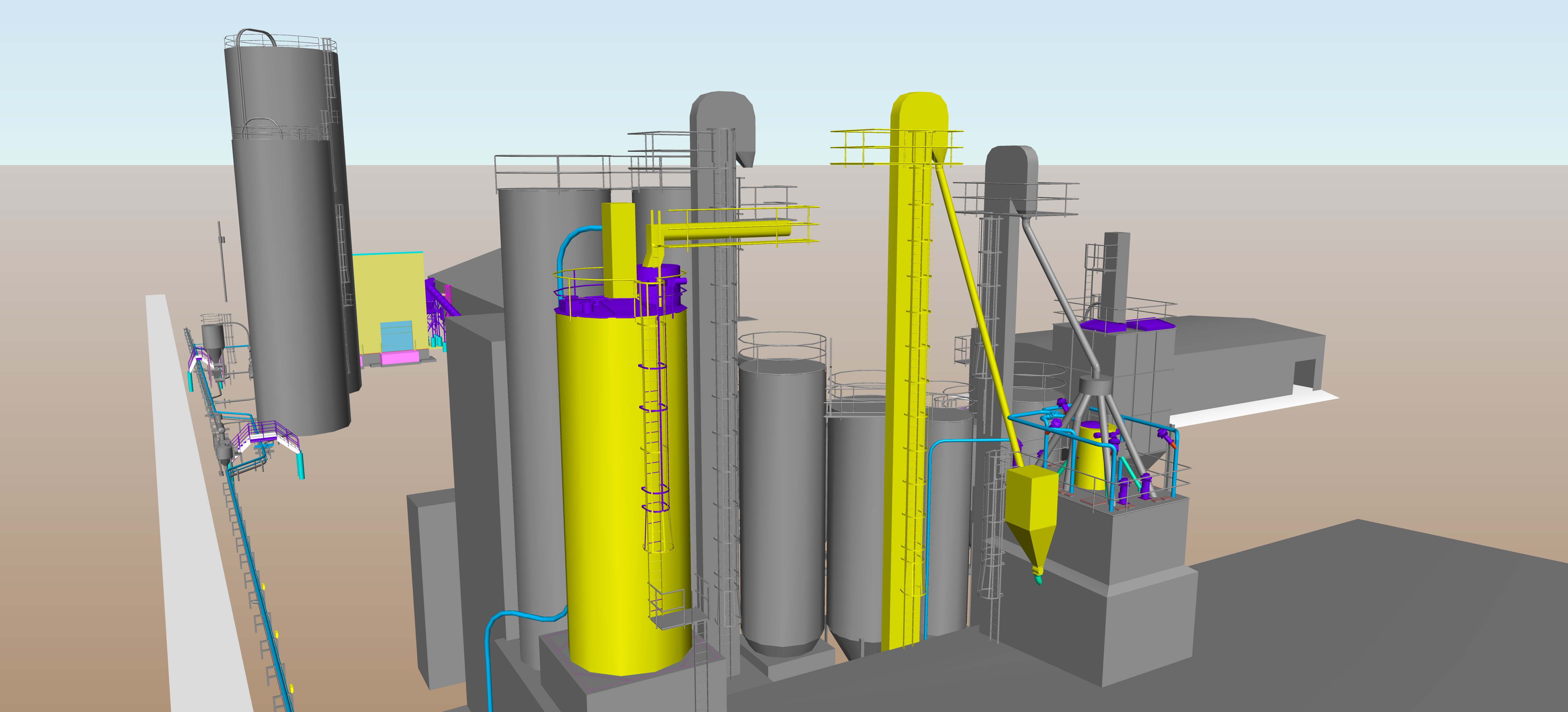

EAPC’s ground-based scanner is a LiDAR system that quickly and very accurately creates a 3D model of its surroundings. On the job site, we are capable of running multiple scans and using software in our office to join the scans together and create one large 3D model, referred to as a point cloud. We then use the point cloud as a template in AutoCAD to draw solid objects to design around.

Scanning allows us to achieve greater accuracy in our field measurements because it removes the human error inherent in pulling a tape measure. This allows us to more accurately design a project and keeps change orders to a minimum.

It is also much faster than using traditional measuring methods, which saves us and our clients time and money.

Scan Any Size

Our equipment is able to capture 3D measurements of objects as small as a pin head or as large as am entire facility.

Measure Faster

Our scanners survey an area virtually, using a point cloud system. These scanners are capable of recording up to one million data points per second, resulting in a much faster and more economical technique than field measuring.

Accurate Measurements

By collecting millions of points, positions and dimensions can be calculated to locate features and determine sizes and shapes with very high accuracy—typically 2mm-4mm for each measurement point.

Scan in Any Light

3D coordinates are captured from any exposed surface that is within the scanner’s range and field of view, even in areas with poor lighting. Laser scanners can operate in complete darkness or bright sunlight.

No Need for Work Interruptions

Laser scanners can capture measurements up to 300 yards, making work interruptions and facility downtime unnecessary.

Collect Data Safely

Hazards are largely eliminated by placing the scanner safely on the ground and in non-hazardous areas. The scanner is also eye safe, so areas do not need to be evacuated or closed off during scanning.

Reduced Site Visits

The data produced from the scan can be used to create virtual models which can be referenced for unexpected questions or future new projects, minimizing return trips to the site.

Multipurpose

Laser scanning can be used to create as-built drawings or recreate lost building prints, create 3D models and virtual images of a facility, and even allow a client to virtually walk-through a facility redesign before it is built. This scanning technology can be applied to Facility Information Management, Building Information Modeling, forensic investigations, and much more.

Cost Savings

Laser scanning allows for lower cost as-builts, less site visits, more accurate as-built drawings, and reduced facility downtime to highlight a few.

Added Value

Laser scanning produces faster, better quality, more complete, more detailed results in a safer, less obtrusive manner than field surveying. The scan data can then be used and reviewed for efficient project management.